Brief Introduction

Bladen Fluorochemicals is a leading company in the manufacturing of high-quality PTFE, ePTFE, and filled PTFE products. With our dedication to excellence and innovation, we have become a trusted name in the industry. Our commitment to delivering superior products, exceptional service, and reliable solutions sets us apart from the competition.

Whether you require standard PTFE components or custom-engineered solutions, our knowledgeable team is ready to assist you every step of the way. We pride ourselves on providing exceptional customer service, prompt delivery, and competitive pricing.

Main Products

- Pure PTFE: We offer a comprehensive range of virgin PTFE products, from PTFE sheets, rods, and tubes to custom-molded components.

- Expanded PTFE: In addition to PTFE, we specialize in manufacturing ePTFE membranes, gaskets, and tapes that exhibit exceptional porosity, making them suitable for various filtration, gasketing, and sealing applications.

- Filled PTFE: Furthermore, we offer a range of filled PTFE products including compounds with fillers such as glass fibers, carbon, graphite, and bronze, providing improved mechanical strength, thermal conductivity, and wear resistance.

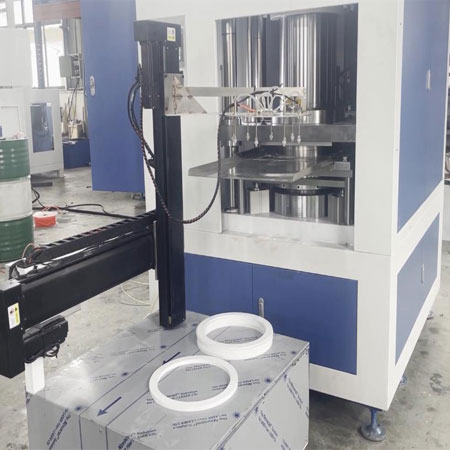

Manufacturing Machines

Our production line includes a range of specialized machines tailored for different processes. These machines efficiently handle various stages of production, including mixing, extrusion, molding, skiving and sintering.

- Extrusion Machine: It is used to convert the blended powder into a solid shape. The extruded PTFE can be in the form of rods, tubes, or other desired shapes.

- Molding Machine: It is used to create complex shapes or components by heating and compressing PTFE powder or preformed billets in a mold.

- Skiving Machine: It is used to produce thin PTFE sheets or films. The machine slices or shaves layers from a PTFE block, resulting in thin, uniform sheets.

- Sintering Furnace: After the shaping process, the PTFE components are sintered in a high-temperature furnace, which helps to fuse the PTFE particles together.

Quality Control

We prioritize quality control at every stage of production. Our dedicated quality assurance team implements rigorous inspection procedures to ensure that our products meet our customer's standards. Here are our standard operating procedure (SOP) for quality control for PTFE products:

- Raw Material Inspection: This begins with inspecting the raw PTFE material's purity and composition requirements.

- Manufacturing Process Control: This includes monitoring temperature, pressure, and other relevant variables during the production process.

- Dimensional and Visual Inspection: This can involve measuring the dimensions of the products against the required specifications using precision tools. Visual inspections are conducted to identify any surface defects, discolorations, or irregularities.

- Mechanical and Physical Testing: This can include tests such as tensile strength, elongation at break, impact resistance, hardness, and thermal stability.

- Chemical Analysis: Conduct chemical analysis to verify the composition and purity of the PTFE products, as well as identify any potential impurities or contaminants that may affect their performance.

Service

Bladen Fluorochemicals is dedicated to providing exceptional service to our customers. We offer:

- Technical support: Our experienced team of customer service and technical experts will assist you in selecting the right type of PTFE products for your applications and addressing any technical queries.

- Customization: We understand that each customer's needs are unique. Therefore, we offer customization options to tailor your PTFE products to specific requirements.

- Timely delivery: We prioritize prompt delivery of orders, ensuring that our customers receive their products on time and within their desired timeframe.