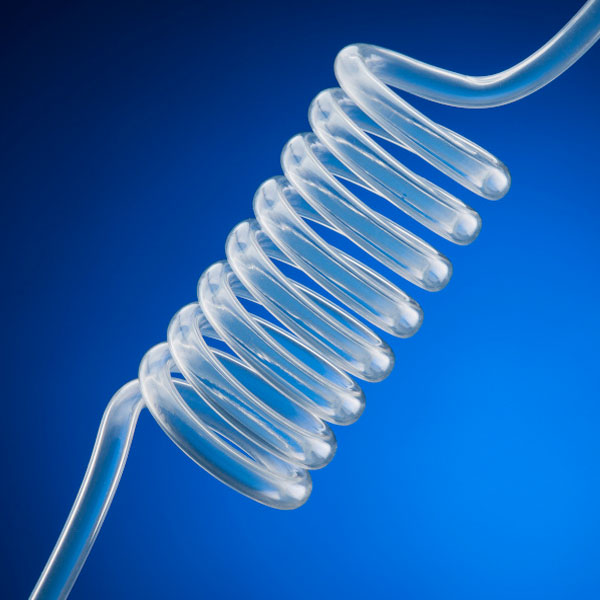

PTFE Coiled Tube Structure

The structure of a PTFE coiled tube is characterized by several parameters: tube ID/OD, wall thickness, coil ID, number of coils, overall length of coils, and length of tails.

- ID/OD and wall thickness: our PTFE coiled tubes can be customized in various inner/outer diameters and wall thicknesses. The inner diameter determines the flow capacity of the tube, while the wall thickness affects the mechanical strength and pressure resistance.

- Coil ID: This refers to the inner diameter of the coiled tube. It represents the size of the central channel through which fluid or gas can flow.

- Number of coils: This indicates how many complete rotations the tube makes around its central axis. It determines the length of the coiled section and affects its flexibility.

- Length of tails: Tails refer to the straight sections at the ends of the coiled tube. These sections are not part of the coiled structure and are used for connection purposes.

Please specify these parameters if you want to request for quotation.

Get In Touch With Us

FAQs of PTFE Coiled Tube

Can your PTFE coiled tubes be straightened if needed?

Can you customize the lengths and diameters of the PTFE coiled tubes?

How do you solve the problem of difficulty in maintaining dimensional accuracy during coiling?

How do you solve the problem of the coiled tube may not being out-of-round due to uneven tension during coiling?

Do you have stock samples? And how to get them?

What are your payment terms?