PTFE Liner Applications

Our PTFE liner has a wide range of applications due to its exceptional chemical resistance, low coefficient of friction, and nonstick properties.

PTFE Lined Pipe

The PTFE liner is applied to the interior surface of a metal pipe, such as carbon steel, stainless steel, or alloy steel. By lining the pipe with PTFE, it provides a protective barrier against corrosive substances and makes PTFE lined pipe suitable for handling corrosive fluids in industries with high-pressure systems.

PTFE Lined Hose

The PTFE lining acts as a barrier between the fluid being conveyed and the hose's outer layer, which is typically made of a flexible material like stainless steel, rubber, or nylon braiding. This combination provides the hose with strength, flexibility, and protection against external factors.

PTFE Lined Valve

The lining of PTFE inside the valve prevents the buildup of deposits or scaling on the valve surfaces. This ensures smooth operation and helps maintain the valve's performance. This lining process is typically be applied on ball valves, butterfly valves, plug valves, and diaphragm valves.

PTFE Lined Vessel

A PTFE lined vessel is a type of container or tank that is lined with PTFE material on the interior surface. The PTFE lining acts as a protective barrier between the contents and the vessel itself. This vessel is used for storing, mixing, and transporting corrosive chemicals and substances

PTFE Lined Reactor

The PTFE lining acts as a protective barrier between the reactive chemicals and the reactor, preventing direct contact between them. This helps to minimize corrosion, contamination, and unwanted reactions with the reactor material. PTFE Lined reactor is widely used in the chemical industry.

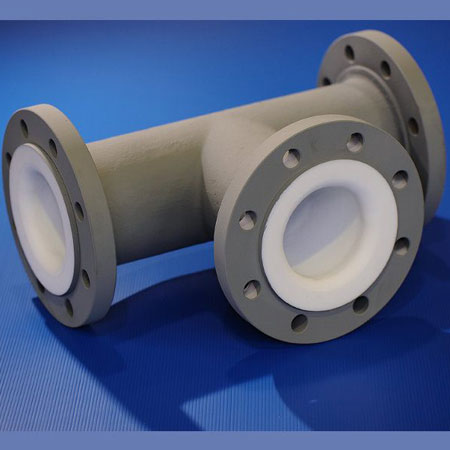

PTFE Lined Flange

PTFE lined flange is used to provide corrosion resistance and reduce friction between the flange and the mating surfaces. It is available in various types and sizes, and has often been used in piping systems, where it can provide a reliable and durable solution for connecting pipes and valves.

PTFE MIG Liner

PTFE liners are popular in MIG welding because they provide excellent wire feeding capabilities, reduce friction between the wire and liner, and prevent the wire from sticking or binding. They are particularly useful when welding with softer and more easily deformed wires, such as aluminum, as they provide a smoother and more consistent wire feed.

PTFE Lined Cap

These caps are typically made of plastic or metal, with the interior surface coated or lined with a layer of PTFE. The PTFE liner provides a chemically inert and leak-proof seal for containers such as bottles, vials, or jars. The PTFE lining acts as a barrier between the contents of the container and the cap material, preventing any potential interactions or contamination.

PTFE Lined Catheter

It consists of a catheter tubing that is coated or lined with PTFE. The PTFE lining helps reduce friction, which can make the insertion and removal of the catheter more comfortable for the patient. It is used in a variety of medical procedures, including intravenous & arterial catheterization, central venous catheterization, and drainage catheters.

Get In Touch With Us

FAQs of PTFE Liners

How do you ensure your PTFE liners will not interact with stored materials?

We will conduct compatibility tests to determine the suitability of our PTFE liner for your specific storage environments.

Can you customize and manufacture the PTFE liner with complex geometry?

Yes, we can customize and manufacture the PTFE liners with intricate or complex geometries by using advanced molding or machining techniques, such as multi-step processes or CNC machining.

Do your PTFE liners require any special maintenance?

Our PTFE liners are relatively low-maintenance and do not require regular upkeep. However, periodic inspections are recommended to ensure the liner’s integrity.

How do you ensure the consistency of PTFE liner thickness?

We use precision manufacturing processes with strict quality inspections to achieve uniform lining thickness.

What are your payment terms?

- For sample orders, Paypal or T/T 100% as a deposit.

- For bulk orders, we request 30% by T/T in advance, the balance to be paid before shipment.