Shapes of PTFE Bushes

PTFE bushes can be manufactured and customized in different shapes and sizes to suit specific requirements.

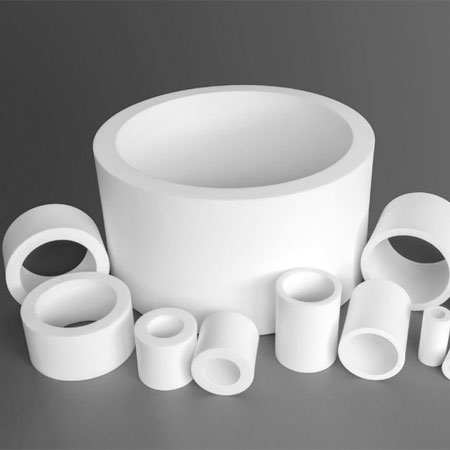

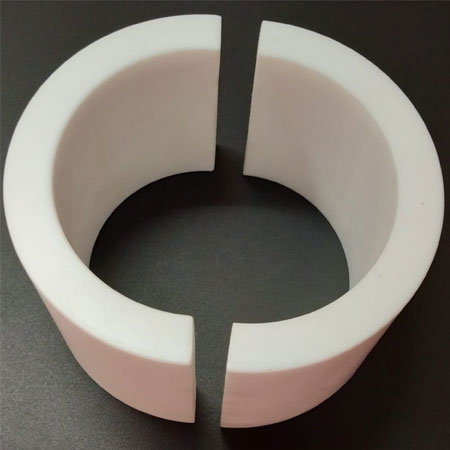

PTFE Cylindrical Bush

This is the most common shape of PTFE bushings. It is a straight, cylindrical sleeve with a central bore through. They are suitable for applications where rotational or linear movement is required. They are often used in machinery, automotive components, and hydraulic systems.

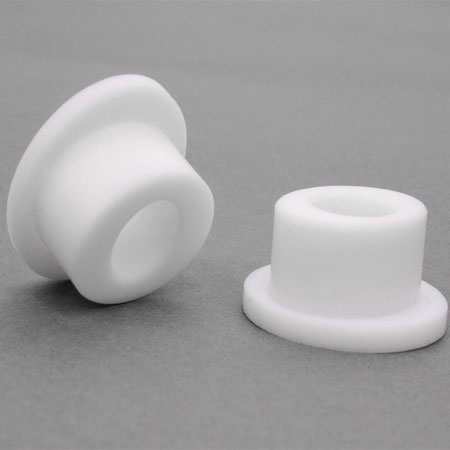

PTFE Flanged Bush

Flanged bushes, also known as flanged bearings, have an additional flange at one end which provides additional stability and helps in proper positioning and alignment. They are suitable for applications where axial movement needs to be restricted, such as pumps, valves, and linear motion systems.

Custom Shapes

PTFE bushes can also be manufactured in custom shapes to meet specific application requirements. Unlike standard cylindrical or flanged bushes, custom shape bushes can be tailored to fit irregularly shaped housings. This allows for a more precise bearing solution for specialized applications.

PTFE Bushes Manufacturing Process

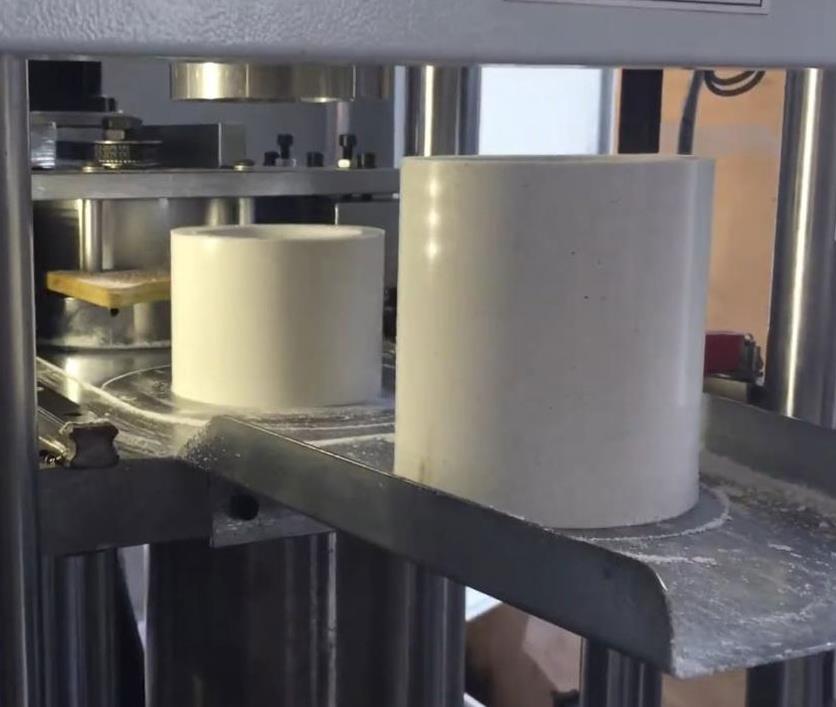

Molded PTFE bushes are typically manufactured through a molding process which allows for better control over the material's orientation, resulting in improved mechanical properties such as strength and wear resistance. It involves compressing PTFE powder (typically blended with additives, pigments or fillers) into the desired shape.

And then sintering it at high temperatures to form a solid material. The sintering process helps the particles fuse together, resulting in a durable and robust PTFE component.

If necessary, the PTFE bushes can undergo surface treatment to enhance specific properties like adhesion. Treatments like etching, plasma, flame or chemical treatment may be applied.

Filled PTFE Bushes

The addition of fillers improves certain properties of the PTFE bushes to meet specific application requirements.

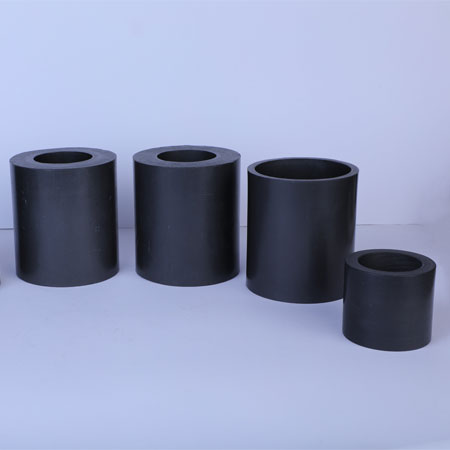

Carbon Filled

The addition of carbon fibers improves the mechanical strength, thermal conductivity, and wear resistance of the PTFE bushes. Carbon-filled PTFE bushes can handle moderate to high loads, and are commonly used in applications where low friction, high strength, and resistance to chemicals are required, such as bearings, seals, and bushings in various industries.

Bronze Filled

The addition of bronze particles can enhance the strength, thermal conductivity, and load-bearing capacity of the PTFE bushes. The Bronze-filled PTFE bushes offer excellent resistance to wear, high temperatures, and chemicals. They are commonly used in heavy-duty applications such as automotive parts, hydraulic cylinders, and industrial machinery.

Glass Filled

The addtional of glass fibers increased the dimensional stability, creep resistance, and mechanical strength of PTFE bushes. Glass-filled PTFE bushes are known for their excellent chemical resistance, low friction properties, and electrical insulation capabilities. They find applications in industries such as chemical processing, electrical, and food processing.

Get In Touch With Us

FAQs of PTFE Bushes

What is your main manufacturing method for PTFE bushes?

Our PTFE bushes are typically manufactured through a molding process. The material is placed in a mold cavity and compressed until it takes on the desired shape.

Can your PTFE bushes withstand extreme pressures?

PTFE bushes have relatively lower mechanical strength and load-bearing capacity, especially when compared to some other materials like metals specifically designed for high-pressure applications.

Can you customize PTFE bushes for our specific applications?

Yes, we can customize your PTFE bushes from dimensions, shape and filler materials to ensure optimal performance and compatibility with your unique application needs.

Do you have stock samples? And how to get it?

Yes, we have a large inventory of PTFE bushes in our warehouse, free sample orders are available for quality check, and the lead time is 5-7 days.

What are your payment terms?

- For sample orders, Paypal or T/T 100% as a deposit.

- For bulk orders, we request 30% by T/T in advance, the balance to be paid before shipment.