Thickness Variations

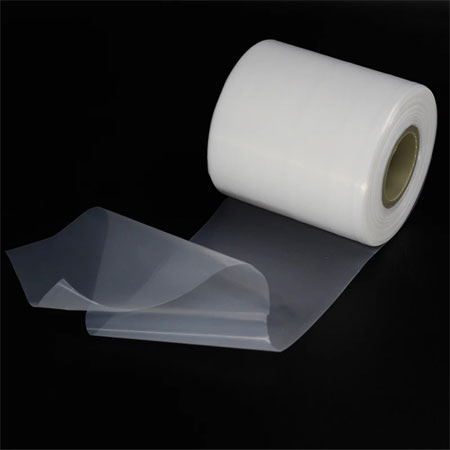

Our PTFE film is produced by extrusion or compression molding of PTFE resin, followed by a process called skiving, which slices the solid PTFE block into thin film. The thickness of PTFE film can vary depending on the specific application. Here are some thicknesses ranges and their applications.

Thin PTFE Film (0.005 - 0.025 mm)

Thin PTFE films are often used as release liners for adhesive-backed materials, such as tapes or labels, or employed as heat-sealing surfaces for packaging applications.

Medium PTFE Film (0.025 - 0.1 mm)

PTFE films in this thickness range are commonly used as electrical insulation for wiring, cables, and circuit boards. They offer excellent dielectric properties and heat resistance.

Thick PTFE Film (0.1 - 0.5 mm and above)

Thick PTFE films are the most rigid among the three options. They are less conformable compared to thinner films and are commonly used as a lining material for tanks, pipes and vessels.